Current Situation

As we know, the heat output of each automotive lighting product is large. Therefore, it is necessary to offer sufficient heat dissipation of the LED to avoid serious light decay when it is working for a long period of time.

As we know, the heat output of each automotive lighting product is large. Therefore, it is necessary to offer sufficient heat dissipation of the LED to avoid serious light decay when it is working for a long period of time.

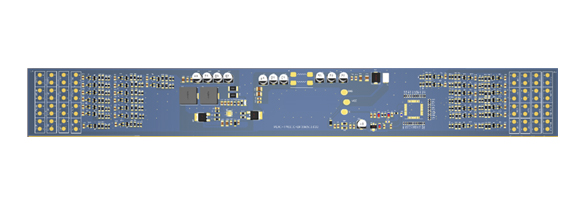

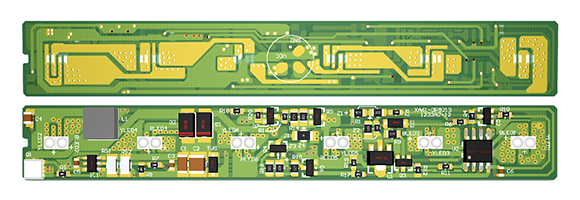

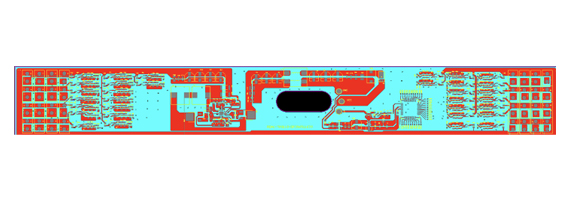

We use FR4 fiberglass board as the raw material of the PCB board. It can optimize the diameter parameters of the heat dissipation control, this assist us in designing sunroofs on the LED that connects the PCB for heat dissipation. This helps us to achieve the vertical heat conduction effect with the aluminum substrate.

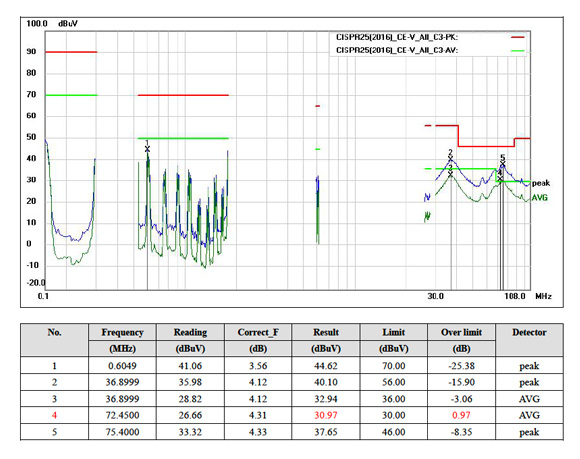

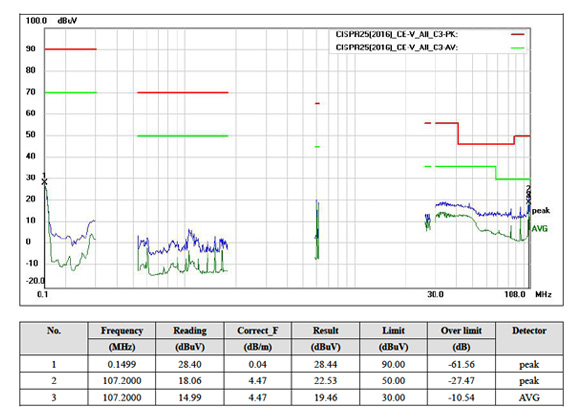

In the automotive industry, the radiation signal generated by the lights should not interfere with other electronic components. Therefore, EMC validation must be considered in the electronic design process of the lamp products.

Our products are designed in accordance with internationally recognized in-vehicle electronic EMC design standard. Shields are added to the drive circuit to reduce the interference between the electronics.

The traditional control flicker mode of light bar can only be controlled by flashing mode for each module. The flashing state of the individual LED boards on each module cannot be controlled separately. Therefore, the diversity of the light bar flashing method cannot meet client’s needs.

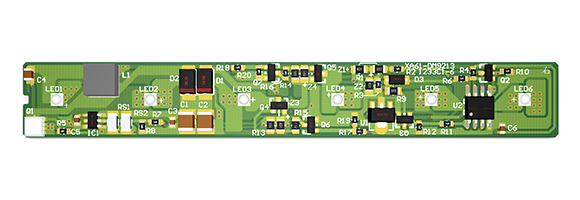

We use the new synchronous rectification drive circuit to achieve control flicker accuracy of light bar to reach each LED panel. This subverts the traditional unit to control the minimum unit, and it has a high anti-interference ability.