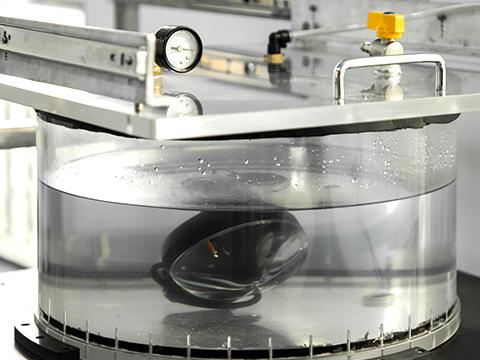

Precise Quality Control

Not only is Smartsun dedicated to the quality of raw materials, but also on the functions and the quality of the finished product. This plays a vital role on our brand building as well as your business.

In our laboratory, each of Smartsun's product passes through all the tests under strict instructions by our experienced workers before packaging.